Battery Webinar Series

Design Battery Packs and Develop Battery Management Systems

7 -22 June 2023

The webinars are free but registration is required.

"Elevating Your Artificial Intelligence Skills with MATLAB and Simulink: A Comprehensive Webinar"

Modeling and Simulation of Battery Systems

Bring your questions over for our Live Q & A

Our Speakers

Learn & Ask your Technical Questions with our team of Application Engineers

Dr Yan Xu

Associate Professor, School of Electrical and Electronic Engineering | Cluster Director at Energy Research Institute Nanyang Technological University, SingaporeDr. Yan Xu has experience working with and supporting clients from a variety of industries who use power system stability, microgrid, and data-analytics areas. He has won the 2021 Best Chapter Award in IEEE Singapore Section, and the General Co-Chair for the 11th IEEE ISGT-Asia Conference 1-5 Nov. 2022, Singapore.

Dr Javier Gazzarri

Principal Application EngineerDr Javier Gazzarri specialise in simulation tools as part of Model Based Design. His work focuses on battery modelling, from cell-level to system-level, parameter estimation for model correlation, battery management system design, thermal management, aging diagnosis, and state-of-charge estimation algorithms.

Zhang XiangChun

Principal Application EngineerZhang Xiangchun has worked with multiple clients on battery and energy storage solutions, particularly in designing Battery Management Systems (BMS) and develop battery models for simulations. By implementing model-based design, he has helped customers accelerate development cycles.

Chirag Patel

Principal Application EngineerChirag Patel specialized in Verification and Validation (V&V), Control System, Modeling and Simulation, Batteries. Chirag Patel works with engineers in control system design to streamline the transition from desktop simulations to real-time testing and hardware-in-loop (HIL) testing.

Topics:

- Battery cell modeling and model parameterization Jun 7th-Close

- Battery pack modeling including cooling plates Jun 14th - Close

- Data-Driven Health Monitoring of Li-Ion Battery Energy Storage System Jun 15th - Close

- Design and test battery management system (BMS) algorithms Jun 22nd

- Show All

Battery cell modeling and model parameterization

This covers new modeling capabilities provided by Simscape Battery, such as Pack Builder API and App, and liquid cooled plates.

Simscape Battery™, a new product in R2022b, has been developed to provide a technology development framework that is assembled specifically to create a bridge between battery cell and battery system. The bridge directly supports upskilling as well as design exploration and design rigor, meaning you can navigate the battery system technology development cycle rapidly and with confidence.

Battery pack modeling including cooling plates

This covers modeling capabilities existed before Simscape Battery release: equivalent circuit model, table-based battery block, and Parameter Estimator in SDO.

Data-Driven Health Monitoring of Li-Ion Battery Energy Storage System

The use of Li-Ion battery energy storage systems (BESS) in industries such as electric vehicles and power grids has increased, but the high cost of BESS makes it critical to accurately estimate its operating cost, which mainly comes from battery degradation.

The health of the battery unit degrades during the charging and discharging process, which is nonlinear and dependent on various factors. This seminar presents a data-driven methodology developed at Nanyang Technological University for online and accurate health monitoring of Li-Ion BESS. The methodology involves extracting health indicators from the charging or discharging process, designing an advanced machine learning model to map the relationship between the health indicators and battery health, and real-time estimation of state-of-health (SOH) and remaining-useful-life (RUL) of the battery. The methodology has been tested on several battery aging datasets and has been licensed to the industry.

Through this webinar, you will learn how to:

1) Define the SOH of the li-ion battery

2) How to extract health indicators from battery aging data set

3) How to design machine learning model for battery SOH estimation

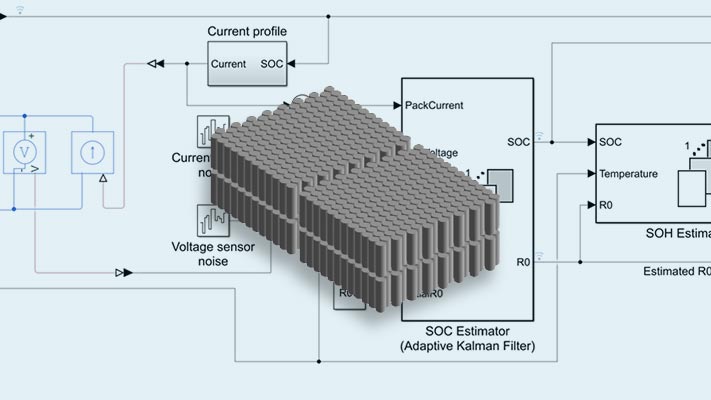

Design and test battery management system (BMS) algorithms

This webinar will demonstrate how engineers can perform hardware-in-the-loop (HIL) testing to validate and test their Battery Management Systems design using Simulink Real-Time and Speedgoat Target hardware.

We will showcase the modeling of a battery pack and battery management algorithms such as SOC estimation and cell balancing using Simulink. The webinar will also show how to perform HIL simulation by running the battery pack plant model in real time on Speedgoat target hardware, to find errors before deploying the actual hardware in the field.

Highlights

1) Modeling and simulation of battery pack in Simulink

2) Review of battery management algorithms in Simulink

3) Performing HIL simulation of Battery Management System using Simulink Real-Time and Speedgoat target computer and I/O hardware